As an experienced cnc enthusiast, i have used a wide range of linear rails over the years. and i have to say that the best linear rails for cnc of 2023 are quite remarkable. they are designed to provide superior accuracy, stability, and reliability when used in cnc machines. whether you are looking for a rail for a 3-axis or 4-axis system, i have narrowed down the list of the best linear rails for cnc this year. so if you are searching for high-quality linear rails for your cnc machine, look no further. check out the list below for the top picks.

Top Picks: Best Linear Rails For Cnc 2023

The Crucial Role Of Selecting The Optimal Linear Rails For Cnc Machines

I have used several Linear Rails for CNC machines in my workshop, and I’m here to tell you why the best Linear Rails for CNC is so important. They are used to guide and support the motion of the cutting tool, allowing for greater accuracy and precision in the cut. The best Linear Rails for CNC can provide smooth, reliable movement and control over the entire system, allowing for maximum productivity. In my experience, the best Linear Rails for CNC are designed for durability, strength, and long-term performance. They are made of high-quality materials that are resistant to wear and tear, and they can be easily adjusted as needed.

This ensures that the machine will remain stable and perform reliably, while also providing a higher level of accuracy in the cut. In addition to this, the best Linear Rails for CNC are also designed to reduce vibration, which can lead to a smoother, quieter operation and improved productivity. They also reduce the amount of dust and debris created by the machine, eliminating the need for regular cleaning and maintenance. Finally, the best Linear Rails for CNC allow for faster cutting speeds, which can reduce the time it takes to complete a project. Overall, the best Linear Rails for CNC are essential for any workshop looking to increase their productivity and accuracy. With the right Linear Rails, you can ensure that your machine will be reliable and perform to its full potential.

So, if you’re looking to get the highest level of accuracy, durability, and performance from your CNC machine, then the best Linear Rails for CNC are an essential part of your setup..

Buying Guide For Best Linear Rails For Cnc

If you’re looking to upgrade your CNC router with linear rails for improved accuracy, then you’ve come to the right place. I’ve been using linear rails for my CNC machine for a few years now, and I’ve learned a thing or two about what to look for. Here’s my helpful guide to buying the best linear rails for CNC machines.

First, it’s important to know the length of the linear rail you’ll need. Obviously, the longer the rail, the more expensive it will be, so factor in how much you’ll need for your CNC machine. I recommend checking your machine’s current rail length and then adding a few inches for good measure.

Next, consider the type of linear rail you’ll need. You’ll have to decide between supported and unsupported rails. Supported rails are more expensive, but they offer more stability and accuracy. Unsupported rails are cheaper, but they’re not as accurate.

Finally, look at the material of the linear rail you’re considering. Stainless steel is the most durable, but it’s also the most expensive. Aluminum is a more cost-effective option, but it will wear out faster.

To sum it up, finding the right linear rail for your CNC machine requires a bit of research. Make sure to consider the length, type, and material of the rail before making a purchase. With this guide in mind, you’re sure to find the perfect linear rail for your CNC machine.

Discover The Top 10 Best Linear Rails For Cnc In 2023: Precision Performance For Your Projects!

What Is A Linear Rail For Cnc?

A Linear Rail for CNC is a type of linear motion guide that provides smooth, accurate, and repeatable movement of a CNC machine along a straight line. It consists of an aluminum or steel rail that is mounted to the CNC machine frame, and a bearing block that slides along the rail to provide linear motion.

What are the benefits of using Linear Rails for CNC?

Linear Rails for CNC offer many benefits, including improved accuracy and repeatability, reduced noise and vibration, increased speed and acceleration, improved load capacity, and increased service life. They also require less maintenance than other types of linear motion guides, and can be easily customized for specific applications.How do I install Linear Rails for CNC?

Installing Linear Rails for CNC is relatively straightforward, and can usually be done in a few simple steps. First, you will need to secure the rail to the machine frame, making sure it is level and properly aligned. Next, you will need to mount the bearing blocks on the rail and adjust the tension on the block screws. Finally, you will need to attach the rail to the machine frame.What type of lubricant should I use for Linear Rails for CNC?

When lubricating Linear Rails for CNC, it is important to use a lubricant that is specifically designed for linear motion guides. Generally, this will be a high-grade synthetic oil or grease, but it is important to consult the manufacturer’s instructions to ensure compatibility.What is the difference between a Linear Rail and a Linear Guide?

Linear Rails and Linear Guides are both types of linear motion guides, but they are not the same. Linear Rails consist of a rail and a bearing block, while Linear Guides feature two parallel linear rails and four bearing blocks. Linear Guides offer more stability and accuracy than Linear Rails, but also cost more and require more space for installation.Related Videos – Linear Rails For Cnc

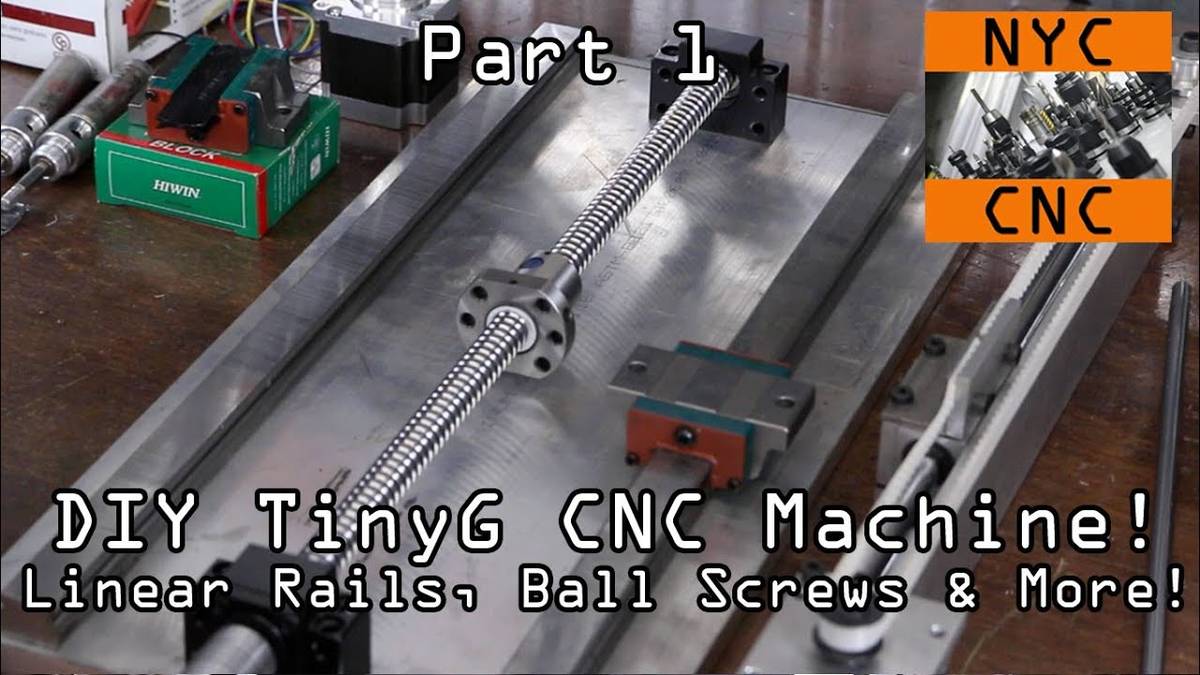

Please watch the following videos to learn more about Linear Rails For Cnc. These videos will provide you valuable insights and tips to help you better understand and choose the best Linear Rails For Cnc.

Cnc Rail Types

Upgrading The $200 Cnc Machine

Final Thoughts On Selecting The Best Linear Rails For Cnc

When selecting the best linear rails for cnc, i believe it is important to consider the following factors: the size and shape of the rail, the load capacity, the accuracy and repeatability of the movement, and the type of bearings used. these factors can help ensure that the linear rails for cnc are suitable for the intended application. if you are still uncertain, i encourage you to reach out for advice from an expert in the field or leave a comment so that others may be able to help.